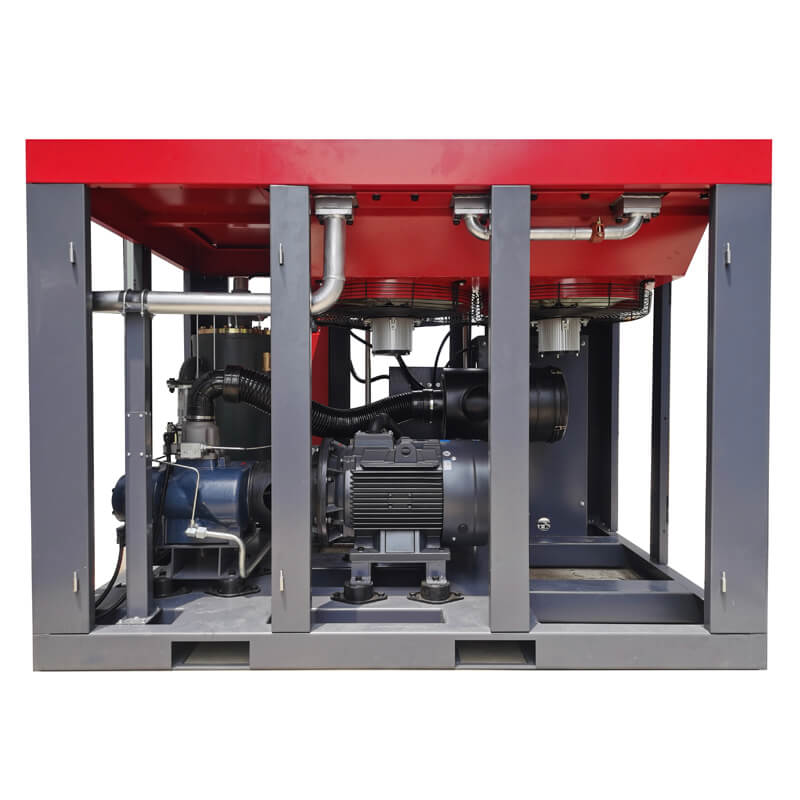

Variable Speed air compressor

Product Name: PM VSD Screw Air Compressor, Variable-speed air compressor

Gas Type: Air

Power: 5.5kw – 315kw

Air outlet diameter: DN20 – DN80

Driven method: Direct driven

Configuration: Stationary

Lubrication Style: Lubricated

Drive method: Variable Speed Drive

Weight: 250-4250kg

Warranty: 2 years

Certification: CE/ASME/ISO

Color: Optional&customization

Local Service Location: Philippines, Mexico, Russia

Compare

1. Application:

heavy&light industry, mining, hydropower, seaport, engineering construction, oil and gas fields, railways, transportation, shipbuilding, energy, military industry, spaceflight, and other industries.

2. Features and Advantages of Sollant Variable Speed air compressor :

(1).Intelligent Control System

Direct display of discharge temperature and pressure, operating frequency, current, power, operating state.Real-time monitoring of discharge temperature and pressure, current, frequency fluctuations.

(2). The Latest Generation High-Efficiency Permanent Motor

Insulation grade F, protective grade IP55, suitable for the bad working conditions.No gearbox design, motor, and main rotor through the coupling directly connected, high transmission efficiency.Wide range of speed regulation, high precision, a wide range of airflow regulation. The efficiency of the permanent magnet motor is higher 3%-5% than the regular motor, efficiency is constant, when the speed drops, still remain the high efficiency.

(3). The Latest Generation Super Stable Inverter

Constant pressure air supply, air supply pressure is accurately controlled within 0.01Mpa. Constant temperature air supply, general constant temperature set at 85℃, make the best oil lubrication effect and avoid high temperature to stop.No empty load, reduce energy consumption by 45%, eliminate excess pressure. For each 0.1 mpa increase of air compressor pressure, energy consumption increases by 7%. Vector air supply, accurate calculation, to ensure that the air compressor production and customer system air demand at all times to maintain the same.

(4). Wide Working Frequency Range To Save Energy

Frequency conversion ranges from 5% to 100%. When the user s gas fluctuation is large, the more obvious the energy-saving effect and the lower the low-frequency running noise, applicable to any place.

(5). Small Start-up Impact

Use frequency conversion permanent magnet motor, start smooth and soft. When the motor starts, the current does not exceed the rated current, which does not affect the power grid and the mechanical wear of the main engine greatly reduces the power failure and prolongs the service life of the main screw machine.

(6). Low Noise

The inverter is a soft start device, the start-up impact is very small, the noise will be very low when start-up. At the same time, the PM VSD compressor running frequency is less than the fixed speed compressor during stable operation, mechanical noise decreases very much.

3. Overall energy saving

Compared with power fixed speed air compressor, the variable speed air compressor has practical significance in energy saving

3.1.The pressure control of variable speed air compressor is precise. It can quickly respond to pressure changes, adjust the speed of the permanent magnet motor, control the pressure fluctuation range within ±0.1bar, stabilize the pressure of the pipe network, provide the necessary air volume with the most reasonable power, and reduce excess energy loss.

3.2.Variable speed air compressor adopts the method of frequency conversion start-up, eliminating the peak current of star-delta start-up and starting smoothly. Reduce the starting power, reduce the impact on the power grid and equipment, and can reduce the equipment operation noise.

3.3.Variable speed control is more excellent than ordinary throttle control. The adjustment range of the flow rate is larger, and with the high-efficiency permanent magnet motor, the energy-saving effect is more significant at a low percentage flow rate.

3.4.Most of the cost in the life cycle of the air compressor is generated by the electricity it consumes. The power consumption of the compressor is closely related to on-site air planning. The variable speed air compressor can not only ensure smooth production but also save considerable electricity costs and achieve a win-win situation for the enterprise.

4. Technical Parameters: