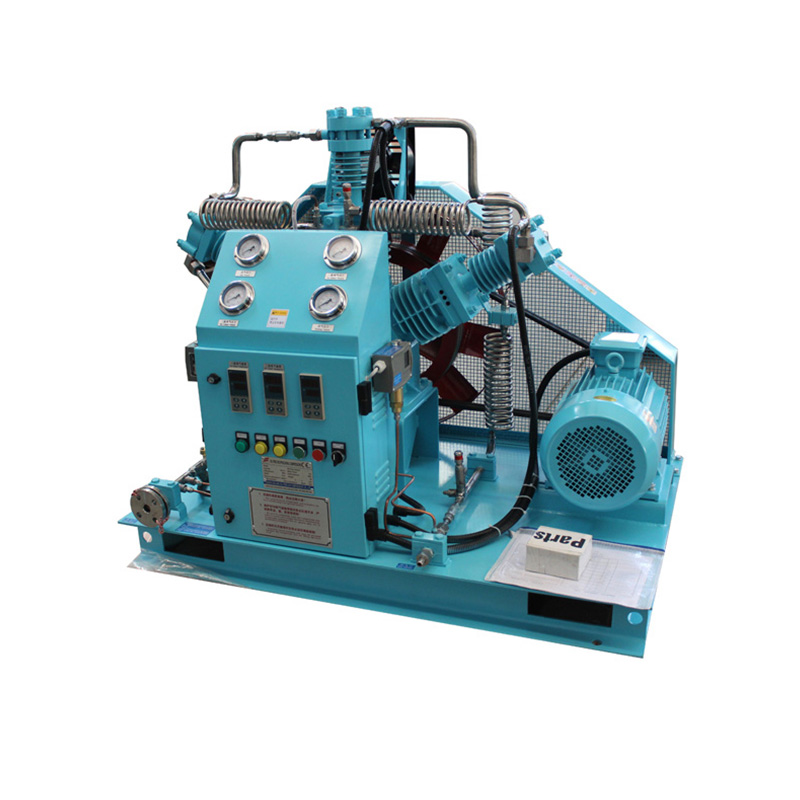

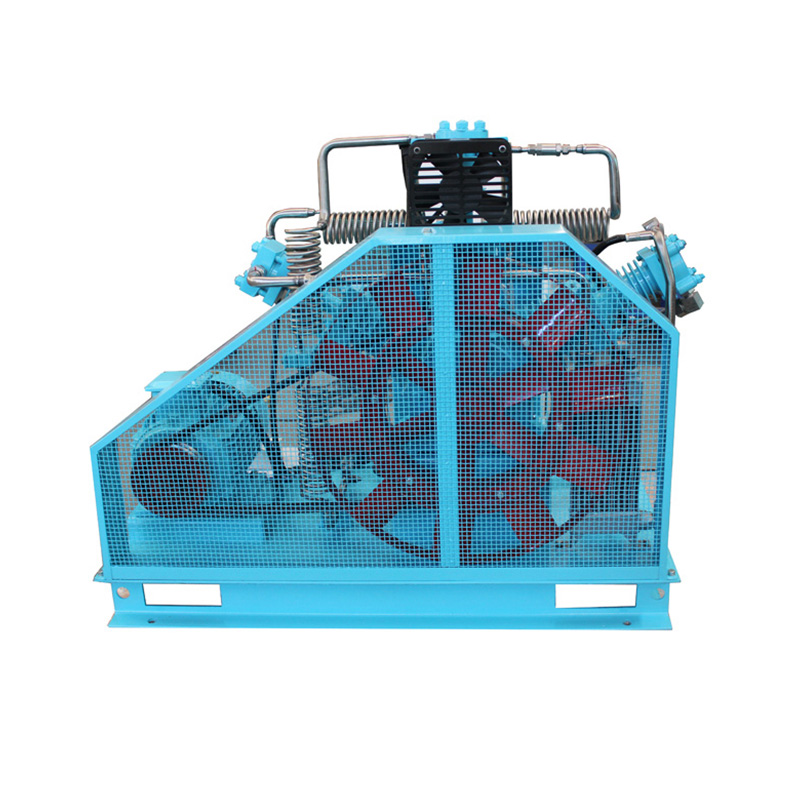

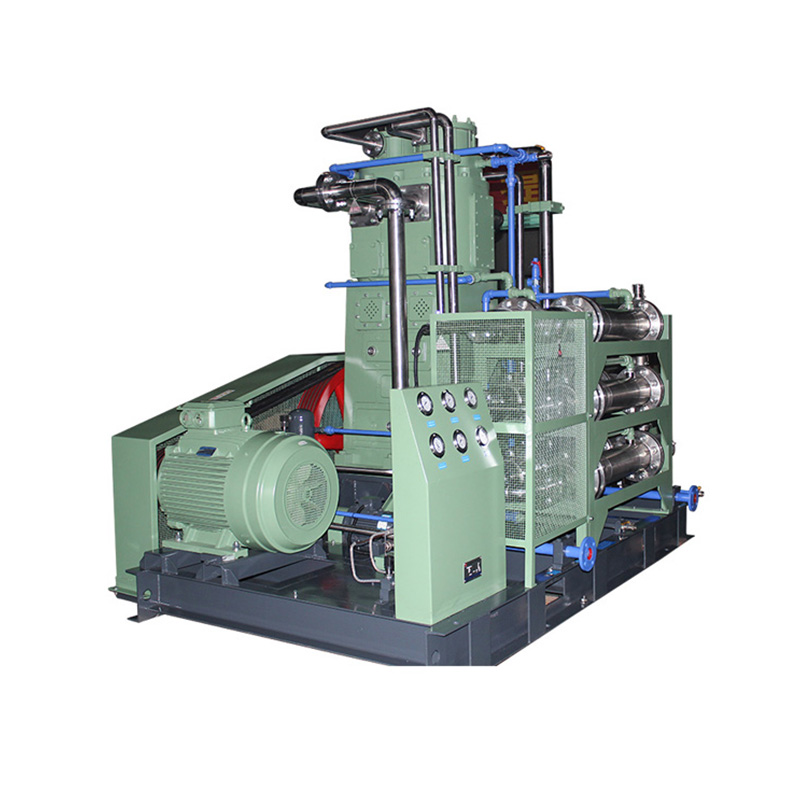

Booster Compressor

*Performance characteristics of oxygen compressor

- Type: Air-cooled or water-cooled type

- Power range: ≤55 KW

- Speed range: 300- 600r/min

- Flow range: 1000 Nm3/h

- Intake pressure: 0-0.6MPa

- Exhaust pressure: ≤10.0MPa

- Compression stage: 1-4Stage

*Performance characteristics of Oil-Free Nitrogen Compressor

- Type: Air-cooled or water-cooled type

- Power range: ≤55KW

- Speed range: 300-700r/min

- Flow range: 3- 1000Nm3/h

- Intake pressure: ≤5MPa

- Exhaust pressure: ≤35MPa

- Compression stage: 1-4Stage

*Performance characteristics of CO2 compressor

- Power range :≤ 55KW

- Speed range: 300-680r/min

- Flow range: 10-800Nm3h

- Intake pressure:≤6.5MPa

- Exhaust pressure: ≤35MPa

Compare

Find Booster Compressor manufacturers from China. Import quality Booster Compressor supplied by experienced manufacturing companies from Sollant Group.

1. Sollant oxygen compressor

Sollant oxygen compressor is total oil-free, does not use any lubricating oil, and for the cylinder use stainless steel material, piston ring itself-lubricated material, all this guarantee oxygen is clean and no pollution.

Compressor working speed is slow, normally 200-400 rpm, to keep working do 24 hours heavy duty loading, this oxygen compressor main use for hospital oxygen supplier center, to increase oxygen supply line pressure to the room, also can boost oxygen, and filing to the cylinder, such as 15Mpa 20Mpa, also our oxygen booster, can use in Industrial acetylene cutting, cutting steel scraping steel factory, support Boiler oxygen combustion cycle the cryogenic liquid oxygen tank vapor oxygen to the tank.

*Advantage of oxygen compressor

(1). Low speed, heavy load design, effectively guarantee the life of wearing parts, and at the same time low noise and vibration.

(2). Small pressure ratio design, and accurate control of inlet and outlet pressure and exhaust temperature at all levels. When the temperature of the machine is abnormal, it will be forced to stop to further ensure the safety of use.

(3). Large diameter and low flow rate design of pipeline valves; further ensure performance and safety.

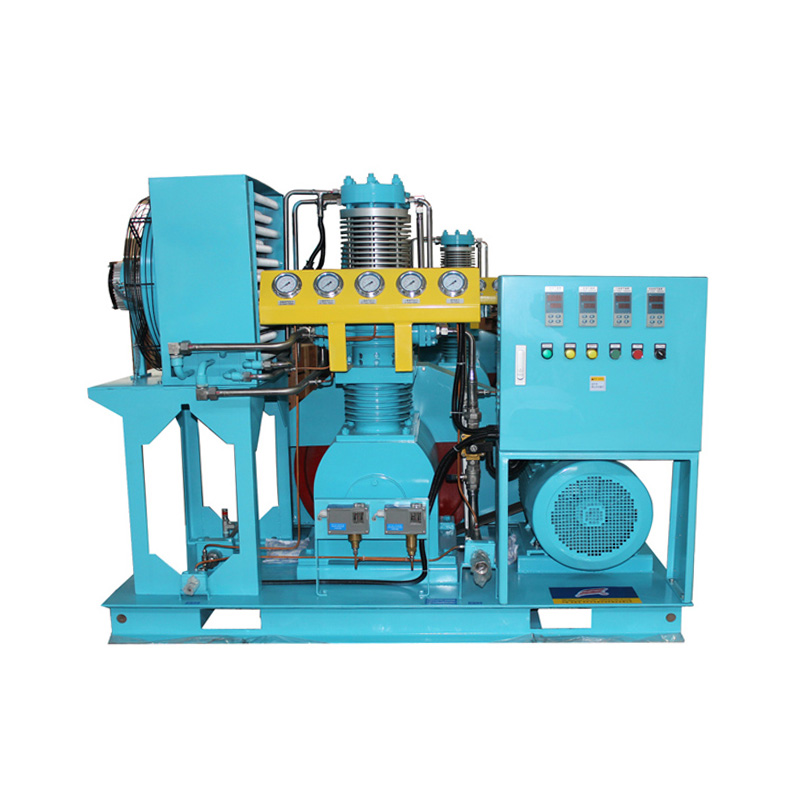

2. Sollant Oil-Free Nitrogen Compressors

The booster is subsequent equipment applied in the field of gas separation, etc; it is widely used in chemical engineering, foodstuff, etc.

Sollant oil-less low and medium pressure series boosters have outstanding features of clean non-pollution and non-leak, each one of production designed to depend on the requirements of customers, easy control, reliable operation, it is your ideal choice. Our company has to produce a high-pressure gas compressor up to 350kg.

*Features of Oil-Free Nitrogen Compressors

(1). All oil-free, green, and pollution-free, no need for oil lubrication.

(2). Friction seals such as piston rings and guide rings are made of special materials with self-lubricating properties, which do not affect the gas composition.

*The structural advantages are reflected in

(1). The entire compression system is not lubricated by thin oil, avoiding the possibility of oil contacting with high pressure and high purity nitrogen;

(2). The whole system has a simple mechanical structure, convenient control, and easy operation;

(3). For the compressed gas medium, there is no pollution, and the nitrogen purity at the inlet and outlet of the compressor is the same.

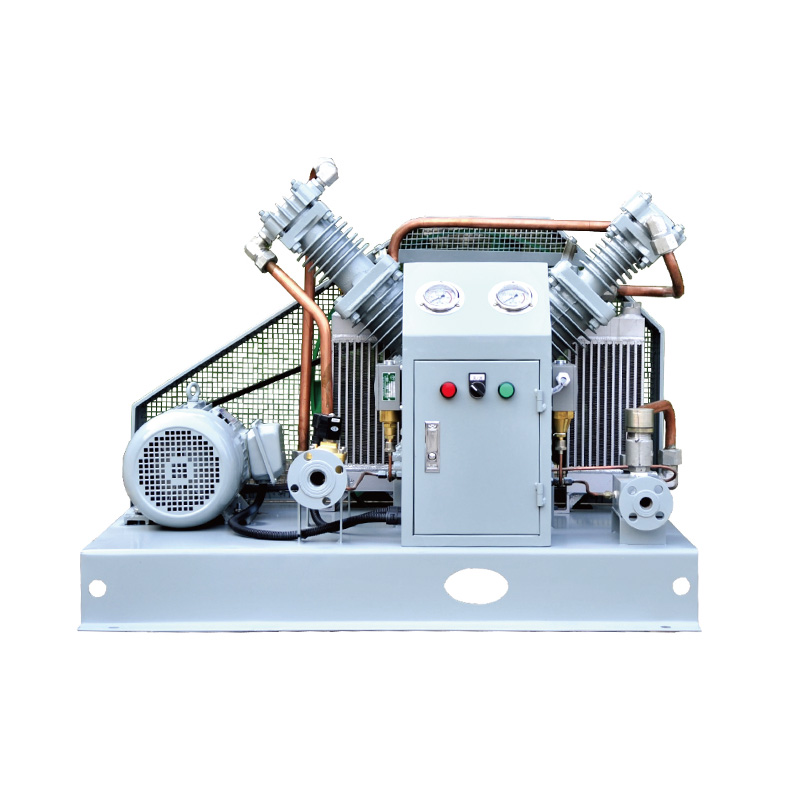

3. Sollant CO2 compressor features

Low speed, no oil, continuous operation, and safe and reliable quality. For the cylinder material, we use stainless steel.

*CO2 compressors can be used in the following conditions

(1). Recover dry ice volatile gas from carbon dioxide plant.

(2). In the carbon dioxide extraction process, the used CO2 is recovered.

(3). Large carbon dioxide compressors are mainly used in urea synthesis equipment.