2-stage low psi air compressor

Working Pressure: 4.0-5.0 〈bar〉

58-73 〈psig〉

Capacity: 4.25-74.81 〈m3/min〉

150-2642 〈cfm〉

Power: 55-280 〈kw〉

75-375 〈hp〉

Noise: 65±3–80±3

Air Outlet: DN65-DN150

Compare

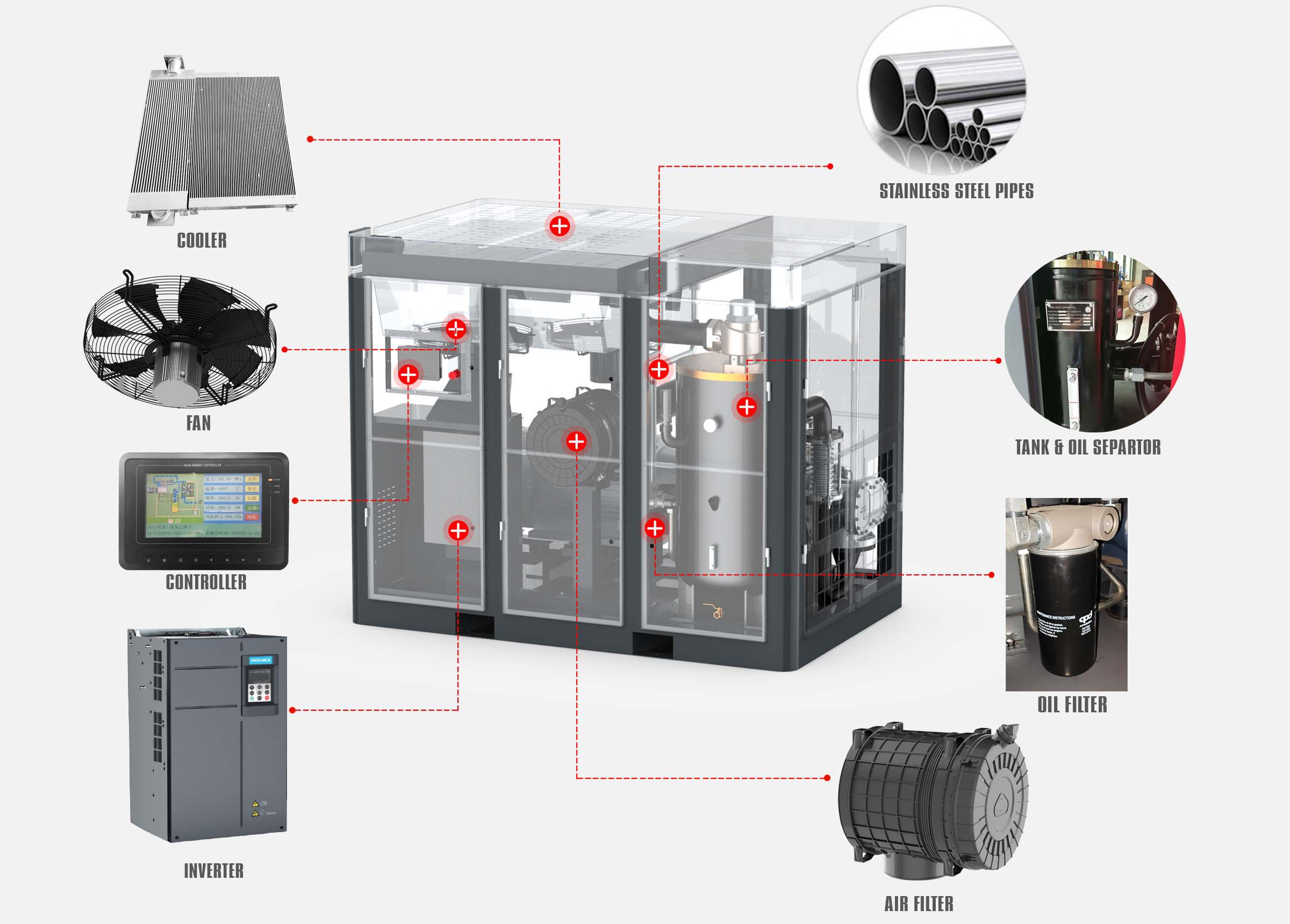

1.Industry-leading low-voltage dual-stage host

- Low voltage + two-stage design, extremely energy-saving.

- The unique intermediate coolant jet curtain design reduces the temperature of the air, and the compression process approaches the most energy-saving isothermal compression. In principle, the two-stage compression saves 5%-8% of energy than the single compression ;

- Two-stage compression, small compression ratio, less leakage, small bearing load, and greatly improved bearing life;

- Adopt the design idea of “large rotor, large bearing, low speed” to reduce noise and vibration, and increase the life and stability of the host ;

- The tooth surface of the rotor is processed by a grinding machine to create a high-precision rotor, which is the first guarantee for the high efficiency and stability of the host ;

2.High efficiency permanent magnet synchronous motor

- IP54 protection level, more stable and reliable than IP23 in harsh environments ;

- Low-temperature rise design, higher efficiency, extending the service life of the motor;

- Use ceramic-plated bearings to completely eliminate the impact of shaft current on the bearings ;

- It is made of rare-earth permanent magnet materials, with large torque during starting and running, and small current during starting and running ;

- Reasonable magnetic field design, magnetic density distribution, the energy-saving motor has a wider working frequency range and low operating noise

3.High-quality and efficient coupling

- The coupling is a torsion elastic coupling with a failure protection function, which can effectively prevent and reduce the vibration and impact generated during operation ;

- The elastic body is only subjected to pressure and can withstand greater loads, and the drum-shaped teeth of the elastic body can avoid stress concentration.

4.Advanced and reliable electronic control system

- The large-size color LCD touch screen has a good human-machine communication interface, and the touch screen has functions of preventing accidental touch and sleep ;

- Customized vector inverter, perfectly matched with the motor, low frequency, and high torque ;

- According to the characteristics of low pressure, special programs are developed to fully monitor various parameters of the machine, and automatically control the state of the machine without special supervision ;

5.Silent centrifugal fan

- The whole system adopts centrifugal fans, which are more efficient and energy-saving ;

- Compared with axial fans, centrifugal fans have higher wind pressure, lower noise, and more energy-saving ;

- Using frequency conversion fan control, the oil temperature is constant, which greatly extends the service life of the lubricant ;

6.High-quality three filters

- The filtration area of the air filter exceeds 150% of the normal requirement, the intake pressure loss is low, and the energy efficiency is good ;

- The oil filter adopts an enlarged imported glass fiber material oil filter design. The rated processing capacity of the oil filter is ≥1.3 times the circulating oil volume, with high filtration accuracy and good durability ;

7.Special valve group

- Intake valve: It adopts a low-pressure special normally-closed butterfly valve, which is stable in work, high in air volume control accuracy, noise reduction design inside, low cavitation noise, and long service life ;

- Minimum pressure maintenance valve: low-pressure dedicated valve, accurate opening pressure, to ensure stable pressure in the barrel, ultra-fast return to the seat, strong sealing, to ensure that the gas does not return, low-pressure loss, and high efficiency ;

Double-stage low-pressure screw air compressor

[supsystic-tables id=10]